Read more »įree training videos for learning Solidowrks grasshopper / Rhino / Kinetic.

#Ironcad to haas gcode windows 10

New windows 10 installed But could not run setup SOLIDWORKS 2016 same software run other system Unable to run SOLIDWORKS installation manager H:\sldlmsldlm.exe Verify that you have access to. Read more »Ĭould not run SOLIDWORKS 2016 setup get this error I would appreciate any advise solving this problem: Cannot make 2 planar end faces to cap the side sheet. Read more »Ĭannot make 2 planar end faces to cap the side sheet Read more »ĭoes anyone have, or know anyone who has, Solidworks 2007 SP0.0 with Crack? I am prepared to pay for it, if necessary.

It then searches for the Installation disk #1, which I have long s. My Solidworks 2007 SP0.0 has suddenly started to throw up the message 'Please wait while Windows configures Solidworks 2007 SP0.0'. Read more »Ĭonfiguration Error with Solidworks 2007 SP0.0

#Ironcad to haas gcode how to

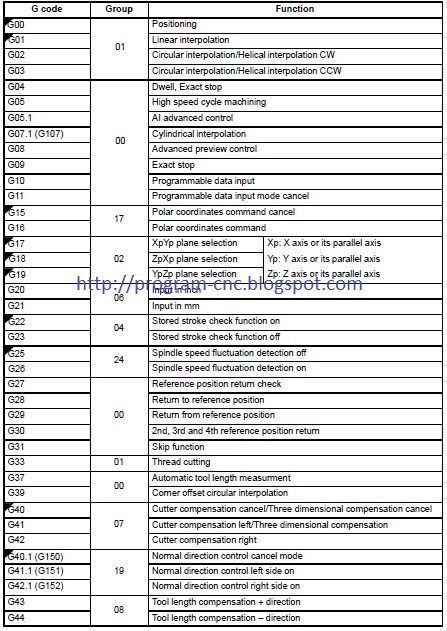

Hi there! Can someone help me how to solve this issue? My macro code: ' ***************** Option Explicit Sub main() Dim swApp As SldWorks.SldWorks Dim swModel As SldWorks.ModelDoc2 Dim swDra. I.D.The most recent discussions How to get Model sketch points coords in Drawings? G77 Live Tooling Flatting Cycle – Optional G80 Cancel Canned Cycle G81 Drill Canned Cycle – Modal G82 Spot Drill / Counterbore Canned Cycle – Modal G83 Peck Drill Deep Hole Canned Cycle – Modal G84 Tapping Canned Cycle – Modal G85 Bore In-Bore Out Canned Cycle – Modal G86 Bore In-Stop-Rapid Out Canned Cycle – Modal G87 Bore In-Stop-Manual Retract Canned Cycle – Modal G88 Bore In-Dwell-Manual Retract Canned Cycle – Modal G89 Bore In-Dwell-Bore-out Canned Cycle – Modal G90 O.D. Stock Removal Cycle Example G72 End Face Stock Removal Cycle G73 Irregular Path Stock Removal Cycle G74 Face Grooving OR High Speed Peck Drill Cycle G75 Peck Grooving Cycle O.D. Point G31 Feed Until skip Function – Optional G32 Thread cutting path – Modal G40 Tool Nose Compensation Cancel G41/G42 G41 Tool Nose Compensation, Left – Modal G42 Tool Nose Compensation, Right – Modal G50 Spindle Speed Maximum RPM Limit (S) – Modal G51 Rapid to Machine zero, Cancel offset G52 Work offset Positioning Coordinate OR Global Work Offset Coordinate System Shift – Modal G53 Machine Zero Positioning Coordinate G54 Work Offset Positioning Coordinate #1 G55 Work Offset Positioning Coordinate #2 – Modal G56 Work Offset Positioning Coordinate #3 – Modal G57 Work Offset Positioning Coordinate #4 – Modal G58 Work Offset Positioning Coordinate #5 – Modal G59 Work Offset Positioning Coordinate #6 – Modal G61 Exact Stop – Modal G64 Exact Stop G61 Cancel G65 Macro Sub-Routine Call – Optional G70 Finishing Cycle G71 O.D. Point G29 Move to Location Through G29 Ref.

Milliseconds G05 Fine Spindle Control Motion (Live Tooling) – Optional G09 Exact Stop G10 Programmable Offset Setting G14 Main-Spindal / Sub-Spindle Swap – Optional G15 Main-Spindal / Sub-Spindle Swap Cancel – Optional G17 Circular Motion XYZ Plane Selection Live Tooling (G02, G03) – Modal, Optional G18 Circular Motion ZX Plane Selection (G02, G03) G19 Circular Motion YZ Plane Selection Live Tooling (G02, G03) – Modal/Optional G20 Verify Inch Coordinate Positioning G21 Verify Metric Coordinate Positioning – Modal G28 Rapid to machine zero return through Ref. G00 Rapid Position Motion G01 Linear Interpolation Motion OR Linear Motion, Chamfer and Corner Rounding – Modal G02 CW Circulation Interpolation Motion – Modal G03 CCW Circular Interpolation Motion – Modal G04 Dwell (P) P=Seconds.

0 kommentar(er)

0 kommentar(er)